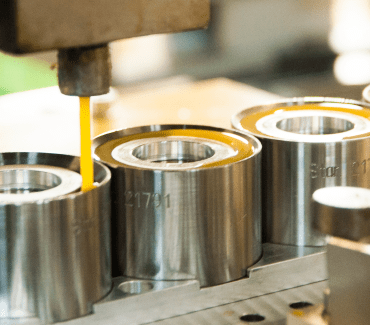

Reconditioning of polyurethane shafts - rubberising and treatment of shafts

We provide a polyurethane shaft regeneration service commonly referred to as 'rubberising'. Shafts are repaired by removing the old polyurethane, rubber or silicone raceway, regenerating the journals and then applying a new, durable polyurethane coating. Reconditioned polyurethane shafts are used in most industries. In doing so, we use tailor-made methods, e.g. by selecting a suitable polyurethane system. Shaft rubberisation is always carried out to order. We are able to carry out virtually any order, regardless of the size of the polyurethane roller or the working environment in which the roller is to operate.

Polyurethane shaft reconditioning - advantages

The effect of rubberising is, above all, a reduction in costs, as it is not necessary to manufacture a new shaft from scratch. This translates directly into faster delivery times for parts to the customer. Smooth and reliable operation of shafts coated with our polyurethane are the main advantages of the service we provide. An additional advantage of shaft reconditioning is the savings.

Reconditioning of polyurethane shafts - quotation

We take an individual approach to each order, which also applies to price. We primarily take into account the working conditions, the size of the order and possible additional services such as pivot repair or balancing. Our customers can count on an optimal solution at a competitive market price.

If you are interested in the professional reconditioning of polyurethane shafts, we invite you to contact us by phone or e-mail, during which we will present a full offer.

Reconditioning polyurethane drive shafts and rollers - why is it worth it?

Rubber is characterised by its high resistance, which allows it to be used, among other things, in areas exposed to abrasion. Rubber- or polyurethane-coated components have very good physical and chemical properties and are easy to recondition. Before the rollers and rollers can be reconditioned, the worn polyurethane, rubber or silicone raceway must be removed. This is followed by the regeneration of the journals and the application of a new coating to the core, made from a suitably selected plastic mixture.

Why coat rollers with high-quality material?

- Cost minimisation. Rubberising the shafts with, for example, EPDM material translates into an increase in the life of the component, so that the owner does not have to buy a new part, but only bears the cost of reconditioning the specific component.

- Rubberising drums allows them to retain their original properties, such as their diameter or corresponding hardness. This is very important in the context of maintaining the relevant parameters of the line of which the roller is an elementary part.

- Rubberising the rollers reduces environmental costs. Rubber roller grinding is environmentally friendly as it minimises waste.

- By rubberising the wheels and rollers, these components become more resistant to high operating temperatures, mechanical influences and many other unfavourable phenomena that could ultimately lead to their damage.

Our services are very popular in many different sectors. We encourage you to take advantage of our company's offer. We guarantee maximum precision and quality in the work entrusted to us.

Why choose us?

We have earned your trust with everything we do

- Effectiveness

- Convenience

- Innovation

Plastics processing is the process of manufacturing plastic products such as polyurethanes. Products such as technical parts, cushioning components and other elastomeric products can be manufactured using polyurethane processing.

ASMA POLSKA is a member of the Austrian Asma Polyurethane Group, one of the leading manufacturers of technical parts made of polyurethane elastomers in Europe, which ensures the high quality of our products. In addition, our experience of more than 30 years and our state-of-the-art laboratory allow us to constantly innovate and introduce the latest technologies.

ASMA POLSKA offers its customers the fulfilment of large-scale and individual orders, the latest solutions in elastomer technology, expert advice, an individual approach to customer needs and constant availability and readiness to cooperate.

ASMA POLSKA is a dynamically developing company whose most important asset is the highest quality of its products. More than 80% of our production is exported to Western European markets, which proves our leading position on the plastics processing market.

Do you need help?

Click the "CONTACT" button, fill in and send the application form. We will contact you within one working day.