- Polyurethane rollers

- Polyurethane wheels and rollers

- Polyurethane screens

- Liwell and Binder mats

- Polyurethane boards

- Polyurethane bushings - polyurethane rods and rings

- Polyurethane scrapers and pulleys

- Polyurethane pipes

- Polyurethane seals

- Slides and tracks

- Elements of the cleaners

- Anti-vibration elements and polyurethane buffers

- Positioning elements

- Other uses

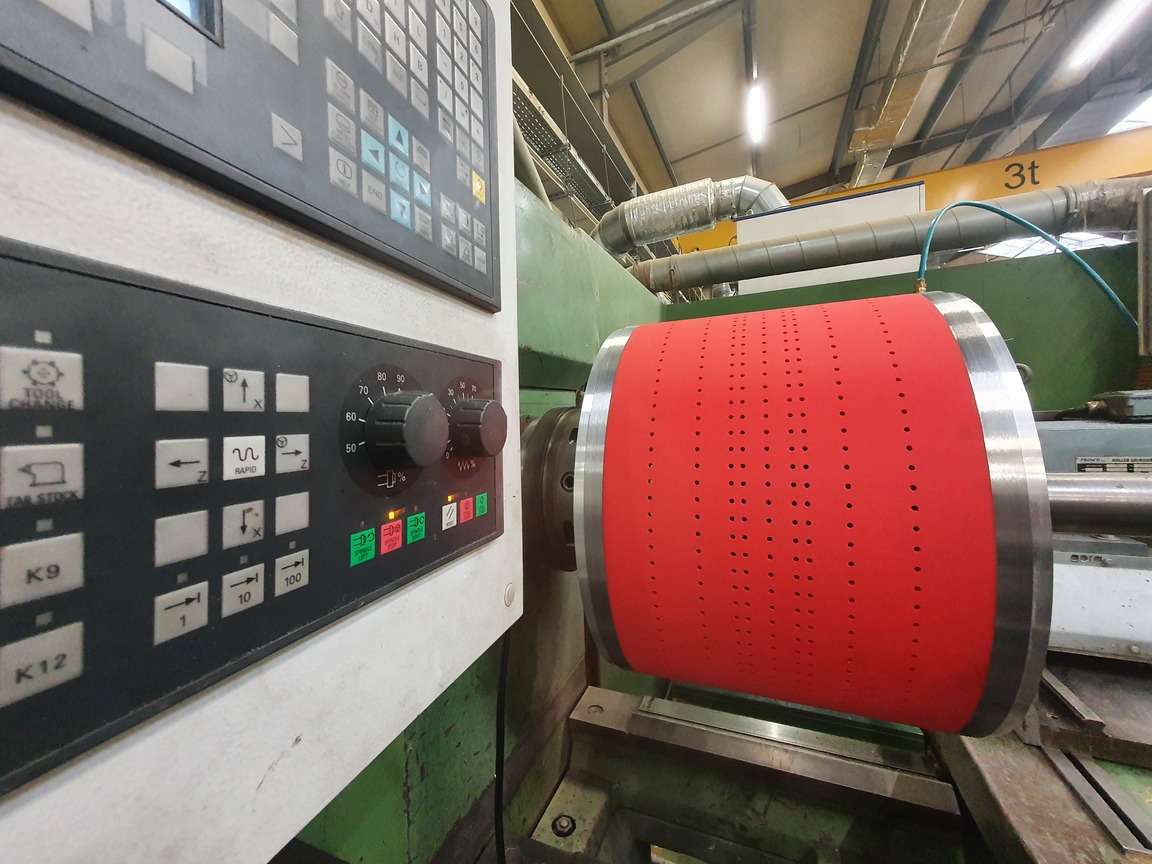

Polyurethane rollers

We recondition shafts of wide-belt grinders, glue and lacquer application machines, as well as all types of rollers and conveyor rollers. We cast shafts of various lengths and diameters. We carry out reconditioning, commonly known as shaft rubberising, up to a diameter of ø=835 mm, length up to 4000 mm. We also manufacture customised cladding for the shafts, which can be of a suitable hardness and colour, as well as indentations on the raceways. As part of our services, we ensure quick turnaround and the highest quality workmanship according to your expectations.

Properties of polyurethane shafts offered by ASMA POLSKA

Polyurethane is an increasingly widely used elastomer in the wider industry. With the right formulation and the right technological process, it acquires unique characteristics that make it successful in very demanding and aggressive working environments.

ASMA POLSKA offers you polyurethane shafts made from scratch, i.e. with a steel part made on the basis of a technical drawing or a model obtained, and a polyurethane coating applied to it. Our polyurethane rollers are characterised by excellent physical and mechanical properties and a high level of precision. Thanks to our many years of experience, thanks to our cooperation with reputable raw material suppliers and thanks to the continuous improvement of our production procedures, our polyurethane shafts are characterised above all by:

- high resistance to cutting, abrasion and deformation,

- high resistance to contact with many chemicals and other aggressive media,

- the ability to operate over a wide temperature range,

- excellent resistance to ageing.

Polyurethane rollers - our production capabilities

The maximum polyurethane shaft we can machine has a diameter of 820 mm and a length of 4000 mm, and we can carry out grinding and grooving operations on such a shaft. If we are unable to machine a polyurethane shaft at ASMA, we outsource such operations. If necessary, we can also balance the shaft.

If you are interested in our polyurethane shaft rubberisation offer, you are welcome to contact our technical advisors.

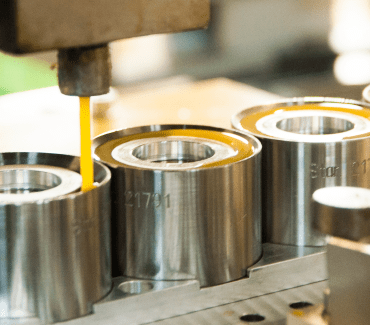

Polyurethane PUR roller - Application of polyurethane details

Rollers made of polyurethane are used primarily in production lines. They are characterised by very good mechanical properties, as well as high abrasion and overload resistance. Polyurethane also benefits from its flexibility, which results in a completely different distribution of forces within the component. Finally, polyurethane is resistant to ageing processes. In this respect, it performs much better than rollers made from other types of material.

A roller made of polyurethane is a detail that can also have very beneficial chemical properties. Parts made from it are resistant to low and relatively high temperatures. What is more, they can withstand direct exposure to aggressive chemicals such as greases, acids, and compounds with a fairly wide pH range.

We offer high performance rollers that are much more advantageous than solutions made from traditional materials. We can manufacture them in a wide range of sizes, tailoring their shape, length and diameter to individual customer needs.

A polyurethane roller is a component that is resistant to adverse operating conditions. The plastic can successfully displace other materials, including metals and ceramics.

Why choose us?

We have earned your trust with everything we do

- Effectiveness

- Convenience

- Innovation

Plastics processing is the process of manufacturing plastic products such as polyurethanes. Products such as technical parts, cushioning components and other elastomeric products can be manufactured using polyurethane processing.

ASMA POLSKA is a member of the Austrian Asma Polyurethane Group, one of the leading manufacturers of technical parts made of polyurethane elastomers in Europe, which ensures the high quality of our products. In addition, our experience of more than 30 years and our state-of-the-art laboratory allow us to constantly innovate and introduce the latest technologies.

ASMA POLSKA offers its customers the fulfilment of large-scale and individual orders, the latest solutions in elastomer technology, expert advice, an individual approach to customer needs and constant availability and readiness to cooperate.

ASMA POLSKA is a dynamically developing company whose most important asset is the highest quality of its products. More than 80% of our production is exported to Western European markets, which proves our leading position on the plastics processing market.

Do you need help?

Click the "CONTACT" button, fill in and send the application form. We will contact you within one working day.