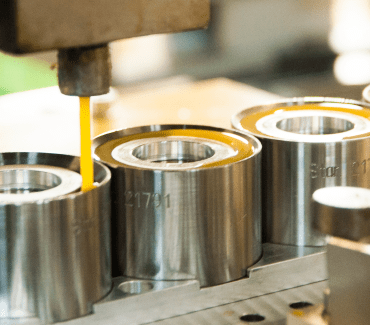

- Polyurethane rollers

- Polyurethane wheels and rollers

- Polyurethane screens

- Flip flow screens mat

- Polyurethane boards

- Polyurethane bushings - polyurethane rods and rings

- Polyurethane scrapers and pulleys

- Polyurethane pipes

- Polyurethane seals

- Slides and tracks

- Elements of the cleaners

- Anti-vibration elements and polyurethane buffers

- Positioning elements

- Other uses

Polyurethane seals - key benefits

At ASMA Poland, we specialise in the processing of polyurethane materials for industrial applications. These are not only used as foams. We tailor the varieties of these polymers for a specific application so that the end product meets exacting requirements. Our state-of-the-art machinery allows for their advanced shaping for a specific project.

Due to its properties, polyurethane has become a reliable material used in technical seals for various types of pneumatics, hydraulics and more. At the same time, it is highly flexible and resistant to damage, making it an ideal raw material for seals. Our polyurethane seals have very good chemical resistance to fats, mineral oils, alcohols and solvents (toluene, heptane, ethyl acetate).

An additional advantage of our polyurethane gaskets is their high resistance to mechanical damage. Compared to rubber or other plastics, polyurethane gaskets are characterised by increased load, abrasion, cutting and high pressure resistance. They are also insensitive to hydrolysis. Flexibility is a key feature of these polymers. This makes the finished parts characterised by low shape memory.

Use of polyurethane seals

Thanks to their physical and chemical properties, our polyurethane gaskets will perform well in a variety of industries: from engineering and automotive to energy and petrochemicals. They are used wherever the gasket must be exposed to high compressive forces. Thanks to its excellent elasticity, this polymer adapts precisely to the shape of the parts on which it is fitted. It therefore fills the smallest gaps, providing an excellent seal. The same elasticity makes it resistant to fatigue damage. As a result, it will perform well in machines for many years.

With a wide selection of polyurethane systems, our advisors will help to select the right material for each customer's needs. We invite both customers who have decided to purchase specific gaskets and those who are just looking for the right solution to contact us. We offer more than just standard, round gaskets.

We are able to meet unusual requirements, moulding seals of non-standard shapes and sizes for enclosures or non-standard connectors. The polyurethane itself is also subject to modifications, for example to increase the tolerable operating temperature or to introduce antistatic properties. We invite you to take a closer look at what ASMA Poland has to offer!

Why choose us?

We have earned your trust with everything we do

- Effectiveness

- Convenience

- Innovation

Plastics processing is the process of manufacturing plastic products such as polyurethanes. Products such as technical parts, cushioning components and other elastomeric products can be manufactured using polyurethane processing.

ASMA POLSKA is a member of the Austrian Asma Polyurethane Group, one of the leading manufacturers of technical parts made of polyurethane elastomers in Europe, which ensures the high quality of our products. In addition, our experience of more than 30 years and our state-of-the-art laboratory allow us to constantly innovate and introduce the latest technologies.

ASMA POLSKA offers its customers the fulfilment of large-scale and individual orders, the latest solutions in elastomer technology, expert advice, an individual approach to customer needs and constant availability and readiness to cooperate.

ASMA POLSKA is a dynamically developing company whose most important asset is the highest quality of its products. More than 80% of our production is exported to Western European markets, which proves our leading position on the plastics processing market.

Do you need help?

Click the "CONTACT" button, fill in and send the application form. We will contact you within one working day.