- Polyurethane rollers

- Polyurethane wheels and rollers

- Polyurethane screens

- Flip flow screens mat

- Polyurethane boards

- Polyurethane bushings - polyurethane rods and rings

- Polyurethane scrapers and pulleys

- Polyurethane pipes

- Polyurethane seals

- Slides and tracks

- Elements of the cleaners

- Anti-vibration elements and polyurethane buffers

- Positioning elements

- Other uses

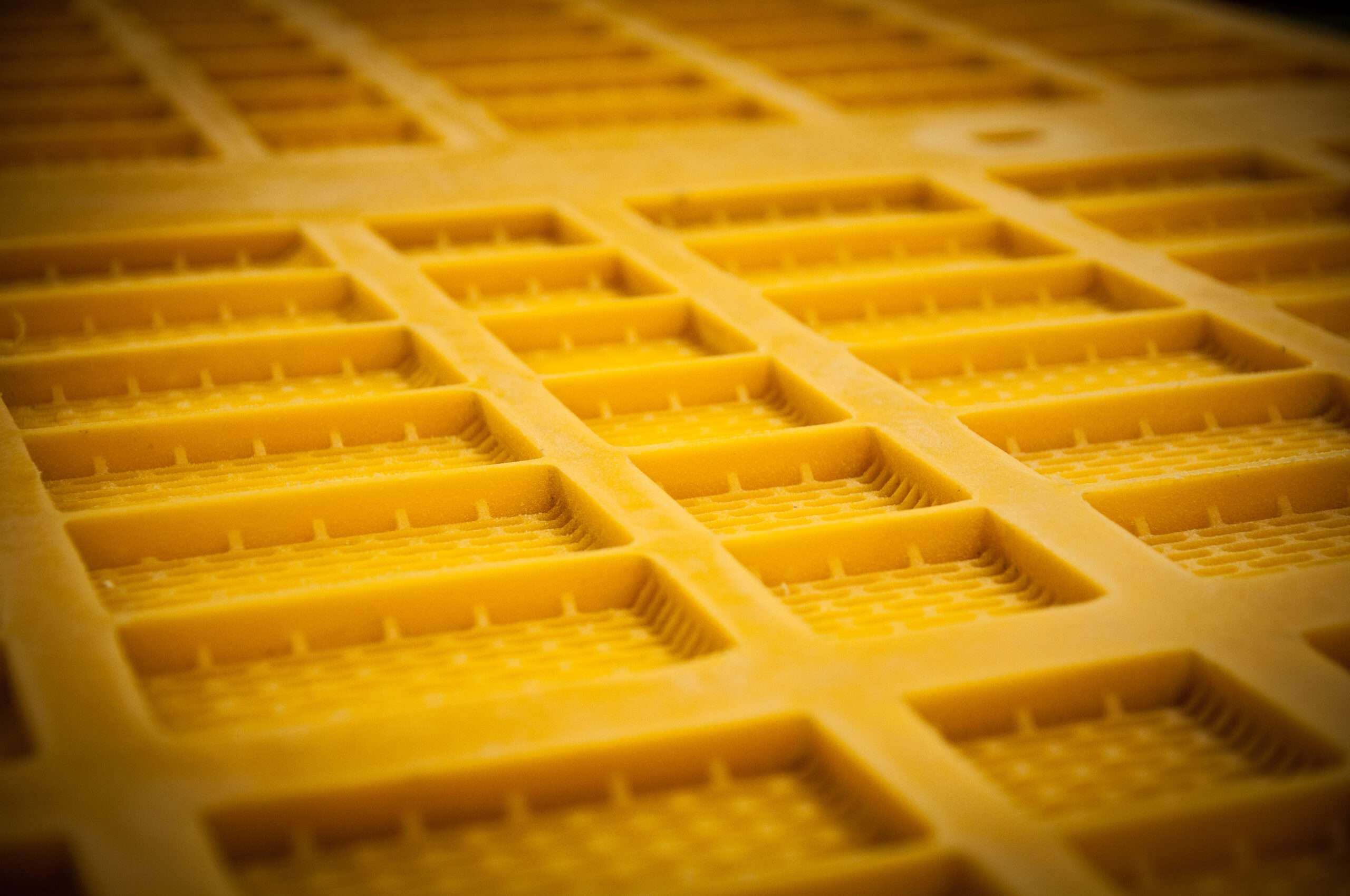

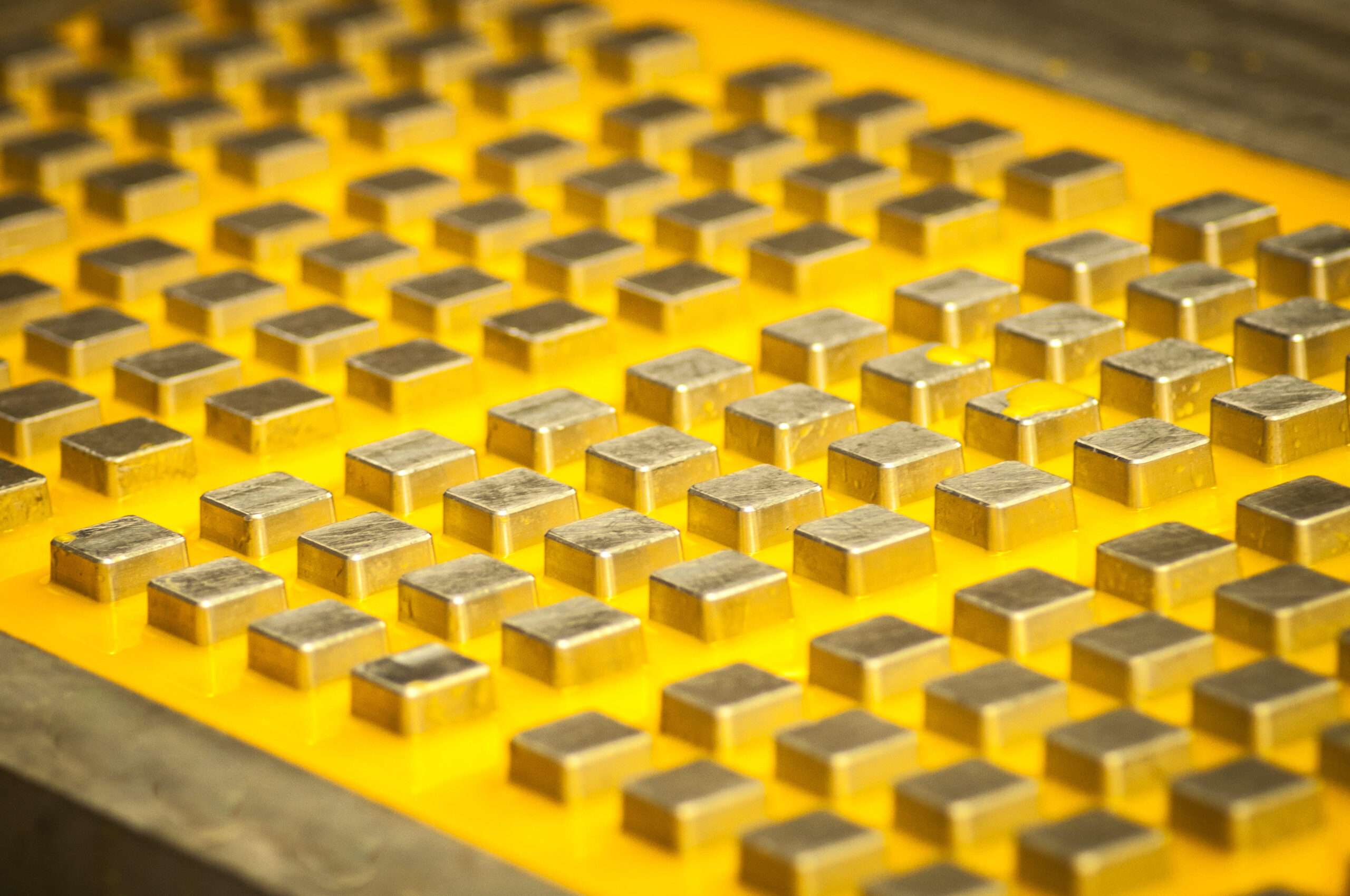

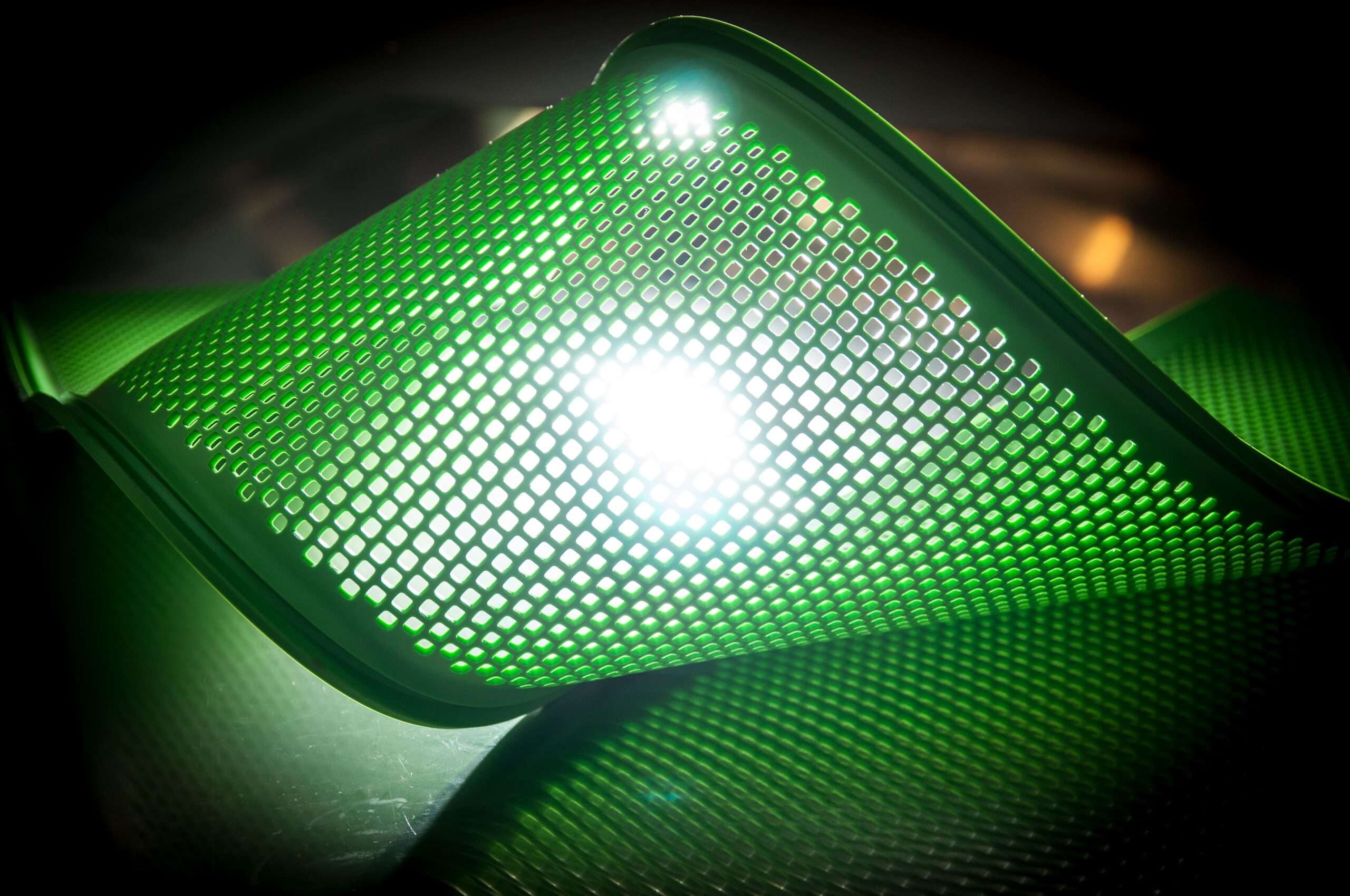

Polyurethane screens

For several years we have been producing high quality polyurethane screenswhich are in operation in many countries in Europe and around the world, such as Germany, Switzerland, the United Kingdom, Austria, the Czech Republic and Russia. We offer a wide range of screens, for most types of screening machines - whether made of polyurethane, rubber or rubber. Customers praise our screens for their high durability, high abrasion resistance, screening precision and interesting technological solutions. Due to our extensive experience in this field, we have been able to solve many problems associated with inappropriate screen selection and thus improve screening technology in numerous well-known mining or recycling plants.

Characteristics of PU material screen products

Polyurethanes are classified as elastomers - cross-linked polymer compounds. They are a diverse group of materials whose properties depend on the raw materials and details of the manufacturing process. Their common feature is their considerable elasticity - under tension they can stretch to a considerable extent and return to their original dimensions. On the other hand, hardness, porosity, solar resistance and, of course, shapes, among others, vary.

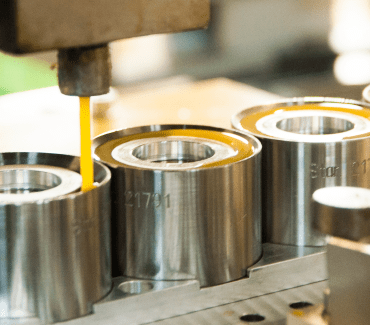

In order to match the properties of manufactured polyurethane elastomers to a specific application, knowledge, practice and special production technologies are required. ASMA POLSKA is a manufacturer with many years of experience. In our offer you will find polyurethane components manufactured by casting, turning, cutting, grinding and milling techniques.

The polyurethane screens offered by our company are an excellent alternative to metal or rubber screens. Very often they are not only more durable than their steel, wire or rubber counterparts, but also more efficient.

Advantages of polyurethane screens from the offer of ASMA POLSKA

The high cost-effectiveness of the sieves offered by ASMA POLSKA is mainly influenced by features such as:

- increased service life even with intensive use;

- high resistance to mechanical damage such as abrasion and cutting;

- insensitivity to corrosion, which is characteristic of steel screens;

- significantly better self-cleaning effect of the sieves compared to sieves made of other materials;

- In an aqueous environment, these screens perform better than rubber, steel or wire screens;

- Their operation makes less noise than rubber or steel screens.

We offer polyurethane screens for a variety of applications. They are used for screening, refining, de-silting and dewatering of various bulk materials.

Please do not hesitate to contact us regarding polyurethane screens. Our advisors will carefully discuss with you the working conditions, the type of material to be sieved. We will then design the sieves to meet your requirements. We will select the right reinforcement, shape and number of meshes and all other parameters for optimal sieve operation. Please do not hesitate to contact us!

Why choose us?

We have earned your trust with everything we do

- Effectiveness

- Convenience

- Innovation

Plastics processing is the process of manufacturing plastic products such as polyurethanes. Products such as technical parts, cushioning components and other elastomeric products can be manufactured using polyurethane processing.

ASMA POLSKA is a member of the Austrian Asma Polyurethane Group, one of the leading manufacturers of technical parts made of polyurethane elastomers in Europe, which ensures the high quality of our products. In addition, our experience of more than 30 years and our state-of-the-art laboratory allow us to constantly innovate and introduce the latest technologies.

ASMA POLSKA offers its customers the fulfilment of large-scale and individual orders, the latest solutions in elastomer technology, expert advice, an individual approach to customer needs and constant availability and readiness to cooperate.

ASMA POLSKA is a dynamically developing company whose most important asset is the highest quality of its products. More than 80% of our production is exported to Western European markets, which proves our leading position on the plastics processing market.

Do you need help?

Click the "CONTACT" button, fill in and send the application form. We will contact you within one working day.